|

The resin used to make

NaturesPlastŠ products

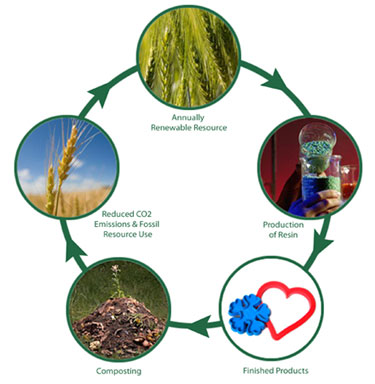

The resin used to make our NaturesPlast~ products is made from 100%

renewable resources from plant starch. The manufacturing process

for these resins takes place at a lower heat than that required for

manufacturing with traditional plastics, further bringing down

the amount of energy used to produce it, as well as reducing the amount of

carbon dioxide produced, reducing green house gasses. Traditional

plastics are petroleum-based and the cost is not subject to fluctuation based

on the price of fossil fuels.

Plant starch-based resin manufacturing is done with bio-polymer

matrix made from renewable, cost-stable resources. These biopolymers

include polylactic acid (PLA), soy proteins, PHA, PHBs, or starch from

corn, wheat or potatoes.

The selected bio-polymer is blended with other biodegradable

components to reinforce its molecular structure. The blend is then polymerized

and treated with nano-composites for surface optimization and further

reinforcement. The entire green composite process is a very

effective alternative to traditional plastic and has a great benefit to our

environment.

Visit our Product Section to see

uses for NaturesPlastŠ

|